Top Bottom Boxes

'Most popular packaging for retail products, minimum order quantity is 2,500 pieces!'

The versatility of top bottom boxes

Top bottom boxes are extremely popular because of their versatile use. They are ideal as promotional packaging, brand packaging or as gift box. In terms of construction, a top and bottom box consists of two separate parts; a top and a bottom. The top falls over the bottom part. A top bottom box can be made (entirely) from folding cardboard, but also (entirely) from solid cardboard or a combination of the two. Top bottom boxes can be produced in a variety of sizes and sizes.

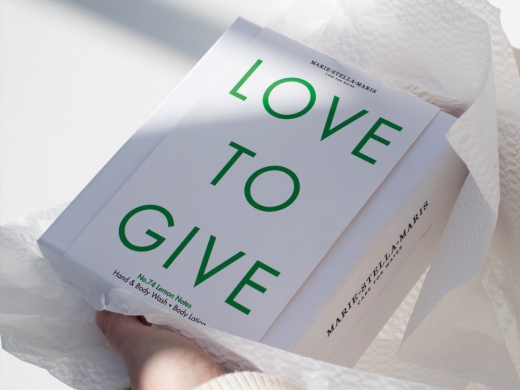

Top bottom boxes with printed cardboard sleeve

To make even more impact with your top bottom box, consider adding a printed cardboard sleeve. A printed cardboard sleeve will be slide over a box. In addition to an extra luxurious and prodessional look, a sleeve also creates extra space for marketing and poroduct information. We can produce sleeves in many shapes and sizes and our sleeves can be printed all-over (also on the inside)! A sleeve can give a packaging a new look without a major investment.

'Give your products an elegant look with a sublime top and bottom box.'

Minimum purchase of a top bottom box is 2,500 pieces

You can order from us from 2,500 pieces top bottom boxes. Fully printed according to your wishes and with your own design. Be inspired by the brands that have gone before you.

Filling top bottom boxes

For many of our customers we arrange the preparation and filling of top bottom boxes for shipment. You supply us with the products and we take care of the rest. For one-stop shopping you have come to the right place at Vrijdag Premium Printing.

Sustainable packaging

For customers who want packaging made of FSC-certified paper or cardboard; Vrijdag Premium Printing has an FSC certificate. This is paper and cardboard that has been harvested in a responsible manner. In addition, it is also possible to opt for new or recycled paper and cardboard. Think of solid cardboard (in different thicknesses), Kraft cardboard, folding cardboard or corrugated cardboard or paper. The choice of material depends on your packaging design, packaging construction and printing. Because the possibilities are endless, one of our packaging specialists will guide you throughout the entire process.

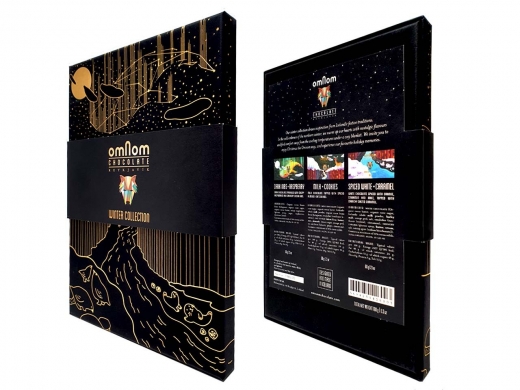

Special printing effects

Add special print effects to a package. It immediately creates added value. As previously written, the packaging is a form of branding. And consumers want to experience a wow factor. The consumer is no longer satisfied with only printing in full color. Special printing enhances the unpacking experience and is incredibly versatile to use. Remember the experience of a brand is one of the main reasons why people choose a particular brand these days.

Top bottom box dimensions (inner / internal size)

Length: minimum 88 mm – maximum 600 mm

Width: minimum 50 mm – maximum 400 mm

Height: minimum 12 mm – maximum 125 mm

Benefits of top bottom boxes

- Premium quality packaging

- Made of solid cardboard or folding cardboard or a combination of both

- All-over printable on the inside and outside

- Available with printed cardboard sleeve

- Available with (printed) interior

- Made with an eye for detail

- Luxury presentation of your products

- Are ready-to-use and can be filled immediately

- Materials are recyclable

- Made in the Netherlands

Questions? Please contact us

Top bottom boxes are a real marketing machines. Would you like to piggyback on this trend? Would you like advice or sparring with an advisor? Please feel free to contact us.

Request for price quote