Interview with CEO Henk Nota in Ampersand 19.1 magazine of Heidelberg

- News

- |

- 01-12-2019

- |

- from Vrijdag Premium Printing

Source: https://bit.ly/35yESac

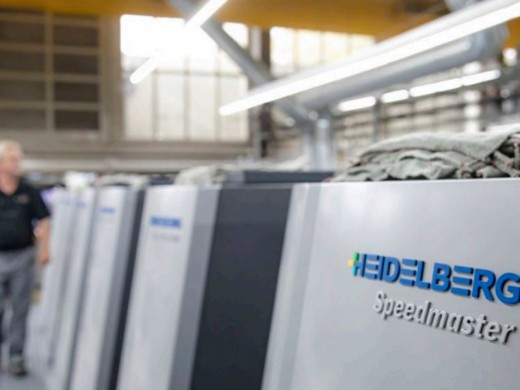

It is remarkably neat and orderly at Vrijdag Premium Printing, we note during a tour. The new 6-color Heidelberg Speedmaster XL 106 is in full production. "We should have bought this press 15 years earlier," says Martin Dekkers, print foreman.

“The Speedmaster XL 106 is much easier to operate than the previous press. More stable too. Moreover, Prinect Inspection Control ensures further quality improvement."

Working group

The new press was installed in mid-February 2019. CEO Henk Nota: “Before that, a working group did research into which press would suit us best. Three suppliers were eligible. After a first test round, one dropped out. It was tempting to stay with our old supplier, but to be honest: Heidelberg is really ahead in terms of technology. The set-up times are short, the print quality is top, the average rotation speed high and the costs per sheet low. The uptime is also fine. Important, because we have established clear KPI's and they must be achieved. After about eight months of practical experience, I can wholeheartedly confirm that we have made the right choice."

Passion

Vrijdag Premium Printing has a huge passion for printing industry. Henk Nota: “With nearly 115 years of knowledge and experience, it is our mission to create a high added value on paper and board. We are a true family business with a social corporate culture. Employees usually stay and work long time for us, knowedge and skills are deeply anchored in the organization. In collaboration with suppliers and machine builders, we like to think - and with success - out of the box. We also offer our customers a one-stop-shop concept. That has everything to do with speed, efficiency, fast work processes and short lead times. As a company we strive for the highest possible service where we can quickly respond to the wishes of the market. ”

He enthusiastically shows examples of various products. From beautiful cigar bands to elegant jewelry boxes. From beer labels to intriguing perfume packaging. From striking shelf talker to innovative packaging for cognac. All examples have one common denominator: high-quality printing. “We have a very wide range of machinery and are therefore able to add special unique refinements to labels and packaging. Companies worldwide know to find us. Around 70% of our turnover is send abroad, to both in- and outside of Europe. An important part of our portfolio is tobacco-related, such as cigar bands and high-quality packaging for cigars and cigarettes. ”

QRM

“About five years ago we changed our production philosophy drastically, inspired by the market. Our customers want to order later but get it delivered faster, in order to reduce their own stocks and capital requirements and reduce costs. We now work according to the method of QRM, Quick Response Manufacturing. Where we previously tried to process as many similar jobs as possible one after the other, the emphasis is now on shortening lead times: all assignments must be delivered as quickly as possible. As a result, there is a huge variety of order flows that run through the company at the same time. We have changed all kinds of procedures and standardized sheet formats. "" To ensure that everything runs smoothly, our organization is "tilted". The hierarchy within individual departments has gradually disappeared and now horizontal cooperation is central. An order no longer goes from sales via in-house sales to work preparation, calculation, purchasing, prepress and planning. All these disciplines are now together on a daily basis, and from there the entire process is prepared, followed and adjusted. A printer or other operator is regularly called in to coordinate whether a run cannot be better prepared or just so. "

Continue to develop

Henk Nota carries on: “To be able to continue to live up to our global position as a leading supplier of luxury labels and packaging, development is crucial. In every sense. We must develop as a company, we must continue to expand our technical possibilities and the development of our employees is vital. We also pay a lot of attention to this in the form of training and the stimulation of multi-employability. In this way people keep a fresh eye and often seemingly fantastic solutions for practical issues arise out of the blue. Thanks to the knowledge and skills of our employees and the drive to realize innovative solutions for our customers, we are capable of innovation continue to deliver at an industrial level. Fantastic!"

About Vrijdag

Vrijdag Premium Printing from Eindhoven specializes in high-quality printing, luxury packaging and premium labels. 115 people work at the company. The company was founded in 1905 by Louis Vrijdag. The current owner Peter Louis Vrijdag (grandson of the founder) is no longer active in business operations. Since 2005, Vrijdag Premium Printing can call itself "Royal Decree" purveyor to the Royal Household. An honorary title and high quality mark. In 2009 the Eindhoven printing company Drukkerij Gestel was taken over.